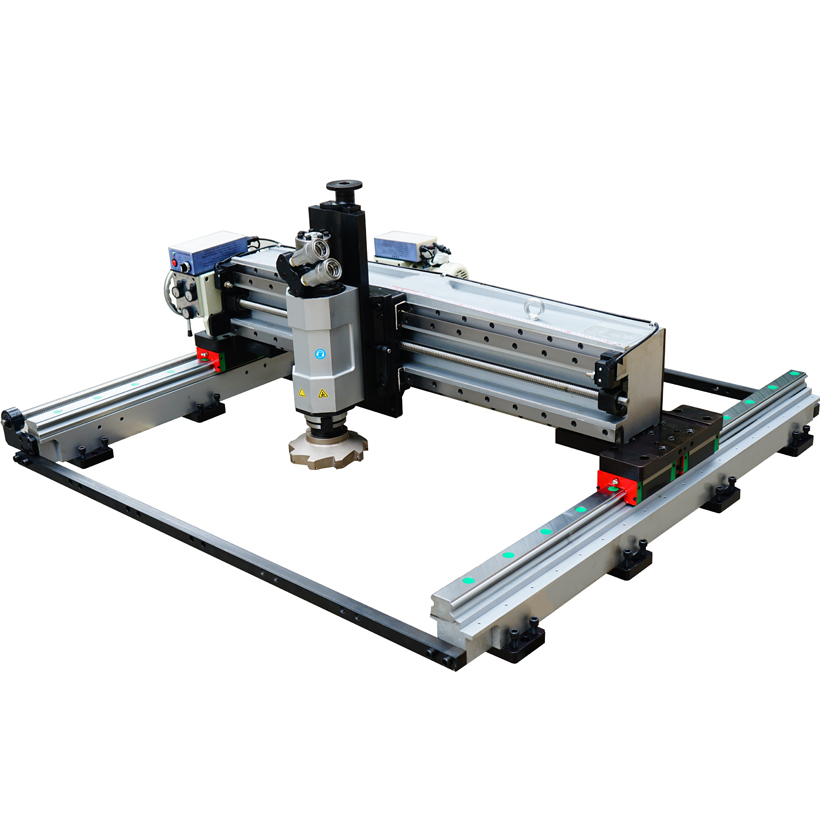

GMM1010 Gantry Milling Tshuab

Paub meej

| Xaxis | 1000 hli |

| Yaxis | 1000 hli |

| Zaxis | 150mm ib |

| X/Y pub | Aua feed |

| Z pub | Kev tuav tes |

| X zog | Hluav taws xob lub cev muaj zog |

| Y zog | Hluav taws xob lub cev muaj zog |

| Milling taub hau tsav (Z) | Hydraulic zog unit,18.5KW (25KW) |

| Milling taub hau ceev | 0-590 Nws |

| Milling taub hau spindle taper | NT40 |

| Txiav txoj kab uas hla | 160mm ib |

| Milling taub hau zaub | High precision digital caliper |

Peb-dimensional saj zawg zog ua ke milling tshuab yog tsim los ntawm txawv modules.

Modules muaj xws li: txaj module, kem module, swb module, hwj chim taub hau module, pub module, positioning module, connectors, fasteners, thiab lwm yam.

Cov qauv sib txawv tuaj yeem ua ke arbitrarily raws li qhov yuav tsum tau ua.

milling tshuab uas tuaj yeem ua ke rau hauv cov qauv sib txawv: cantilever milling tshuab, kem milling tshuab, gantry milling tshuab, thiab lwm yam milling tshuab.

Nws tuaj yeem ua ke rau hauv cov tshuab milling ntawm txhua qhov ntev thiab dav.

Txais yuav high-precision, txhim khu kev qha actuators, nrog zoo stability, durability thiab dynamic teb.

Nws muaj cov yam ntxwv ntawm siab rigidity, siab precision thiab compact qauv.

Nws muaj cov yam ntxwv ntawm siab horsepower thiab stepless ceev tswj ntawm tas li torque ntawm ntau yam speeds.

Lub zog txiav yog loj, thiab txiav qhov tob tuaj yeem ncav cuag 5 hli thaum lub sijhawm ua haujlwm ntxhib;

High machining raug, nto roughness tuaj yeem ncav cuag Ra3.2 thaum ua tiav

Kev ua tau zoo

1. Modular tsim, yooj yim rau nruab thiab khiav lag luam, lub zog muaj zog.

2. Forging lub txaj tseem ceeb los ntawm ntau qhov kev kho cua sov, nruab nrog siab precision linear phau ntawv qhia rau kev txiav txim siab tsis tu ncua.

3. Lub txaj tseem ceeb yog nrog khib thiab pinion tsav qauv uas muaj extensibility.

4. Milling caj npab yog ua los ntawm Steel phaj, lub zog muaj zog yog ruaj khov.

5. Ob leeg X thiab Y axis pub tau txais, Z axis pub manually thiab nruab nrog qhov siab digital nplai.

6. Lub zog tsav yog siv hydraulic.Nws yog nruab nrog ib txheej ntawm hydraulic zog chav tsev uas muaj peb hom fais fab tso zis, uas muaj peev xwm cais txaus siab spindle milling taub hau thiab X thiab Y axis pub tau txais nrog cov chaw taws teeb tswj lub thawv,

7. Spindle milling lub taub hau tuaj yeem siv ntau yam qauv hydraulic lub cev muaj zog, uas tuaj yeem ua tau raws li qhov sib txawv txiav ceev.

8. Lub tshuab milling kuj tau txuas ntxiv nta.Qhov ntawd yog hais tias, lub tshuab gantry milling no tuaj yeem hloov pauv mus rau hauv lub dav hlau monorail milling tshuab.Functional applicability zoo heev.